Sensor Calibration 2.5.10

General Information: Leica Geosystems instruments are manufactured, assembled and adjusted to the best possible quality. During the manufacturing process, the instrument errors are carefully determined and set to zero. When the instrument is in use, though, and exposed to external influences, errors can increase and it is highly recommended to redetermine them in the following situations

• Before the first use

• Before every high precision survey

• After rough or long transportation

• After long working periods

• After long storage periods

• If the temperature difference between current environment and the temperature at the last calibration is more than 20 °C

Quick temperature changes, shock or stress can cause deviations and decrease the instrument accuracy.

To get precise measurements in daily work, it is thus important:

• To check and adjust the instrument from time to time.

• To take high precision measurements during the check and adjust procedures.

• To measure targets in two faces. Some of the instrument errors are eliminated by averaging the angles from both faces.

Check and adjust can be done in the field by running through specific measurement procedures. The procedures are guided and must be followed carefully and precisely as described in the following chapters. Some other instrument errors and mechanical parts can be adjusted mechanically.

Mechanical adjustment

The following instrument parts can be adjusted mechanically:

• Circular level on instrument and tribrach

• Optical plummet - option on tribrach

• Allen screws on tripod

Electronic adjustment

The following instrument errors can be checked and adjusted electronically:

l, t Compensator longitudinal and transversal index errors

i Vertical index error, related to the standing axis

c Horizontal collimation error, also called line of sight error

a Tilting axis error

ATR ATR zero point error for Hz and V - option

☞ If the compensator and the horizontal corrections are activated in the instrument configuration, every angle measured in the daily work is corrected automatically.

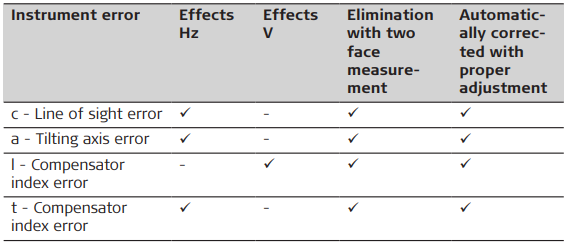

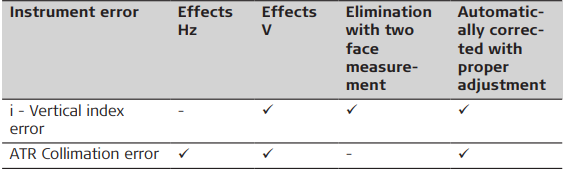

Impact of errors that can be adjusted electronically

Preparation

☞ Before determining the instrument errors, the instrument has to be levelled using the electronic level. The tribrach, the tripod and the underground should be stable and secure from vibrations or other disturbances.

☞ The instrument should be protected from direct sunlight to avoid thermal warming. It is also recommended to avoid strong heat shimmer and air turbulence. The best conditions are early in the morning or with overcast sky.

☞ Before starting to work, the instrument has to become acclimatised to the ambient temperature. Take at least 15 minutes into account or approximately 2 minutes per °C of temperature difference from storage to working environment.

☞ Even after adjustment of the ATR, the crosshairs may not be positioned exactly on the centre of the prism after an ATR measurement has been completed. This outcome is a normal effect. To speed up the ATR measurement, the telescope is normally not positioned exactly on the centre of the prism. These small deviations/ATR offsets, are calculated individually for each measurement and corrected electronically. This means that the horizontal and vertical angles are corrected twice: first by the determined ATR errors for Hz and V, and then by the individual small deviations of the current aiming.