How to Use Machine Calibration 9.5

Machine calibration workflow:

The iCON site software offers a simple workflow for a Machine calibration. Calibration results are automatically stored in the internal memory of the controller. Additionally, the results can be saved to a USB stick. Transferring the results to the machine control system using a USB stick helps to decrease installation time.

The MC Calibration application is available for:

• Single-Boom Excavator

• Dual-Boom Excavator

• Wheel Loader

• Snow Groomer

• On-Cab Dozer

• Tower Mounted Driller/Body Mounted Driller

• Tower Mounted Piler/Body Mounted Piler

The different workflows are described in the following chapters.

➜ Before starting the machine calibration, ensure that the machine is placed on a flat solid surface where it cannot move or sway.

➜ Take care to use correct settings for Prism Type and Prism Height when measuring the machine.

➜ Always adhere to the instructions in the display.

➜ When the calibration is done, enter or load the calibration results to the machine. Do not move the machine before the values are entered in the machine control system.

➜ For excavators, more calibration options are available. Refer to 9.5.3 Additional Calibration Options for Excavators .

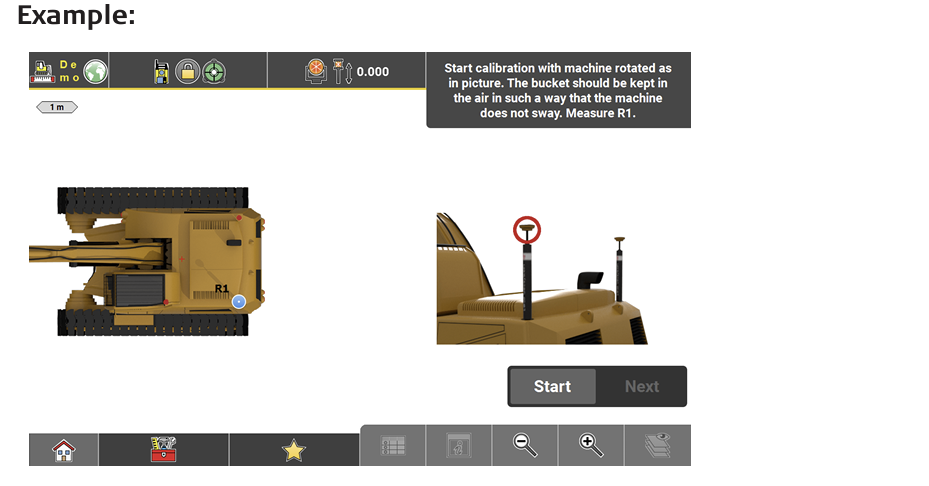

The calibration screen

The calibration screen is intended to guide you through the calibration process. The screen consists of two sections:

• Map screen (left section): This section displays a photorealistic picture of the machine and the position of the points to be measured. You can zoom and pan the picture if necessary

• Instructions and navigation (right section): This section displays instructions as well as a detailed picture of the current point to be measured. Once all points in the current step are measured, tap Next to proceed to the next step.