Adjusting Blade Wear/Calibrating a Dozer Cutting Edge

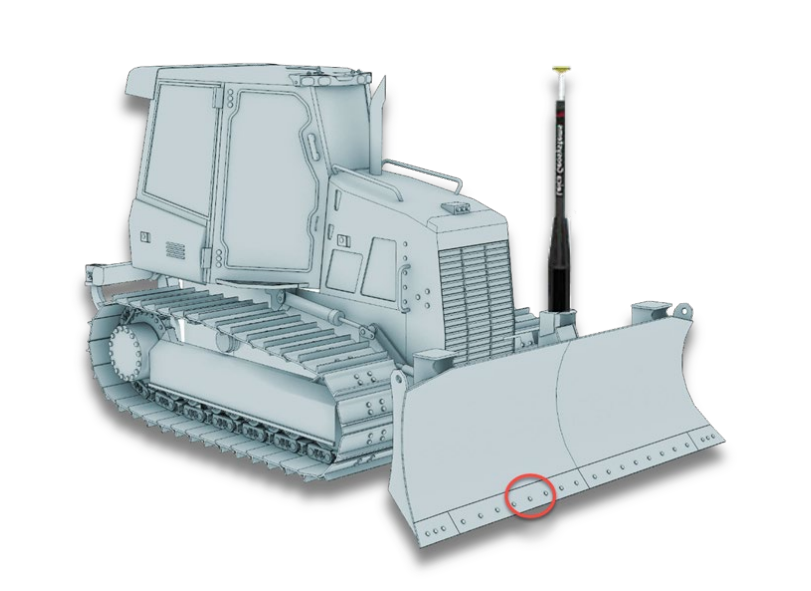

Bulldozer blades/cutting edges are sacrificial and designed to wear down after repetitive use, preventing damage to the dozer and offering a replaceable part. Due to the fact that the Machine Control systems calculate the position of the blade based on measurements from GNSS antennas or laser receivers, the distance to the blade needs to be adjusted as the blade wears, or when the cutting edge has been replaced. MC1 offers an easy to access setting which allows users to frequently adjust this measurement.

Adjusting Blade Wear

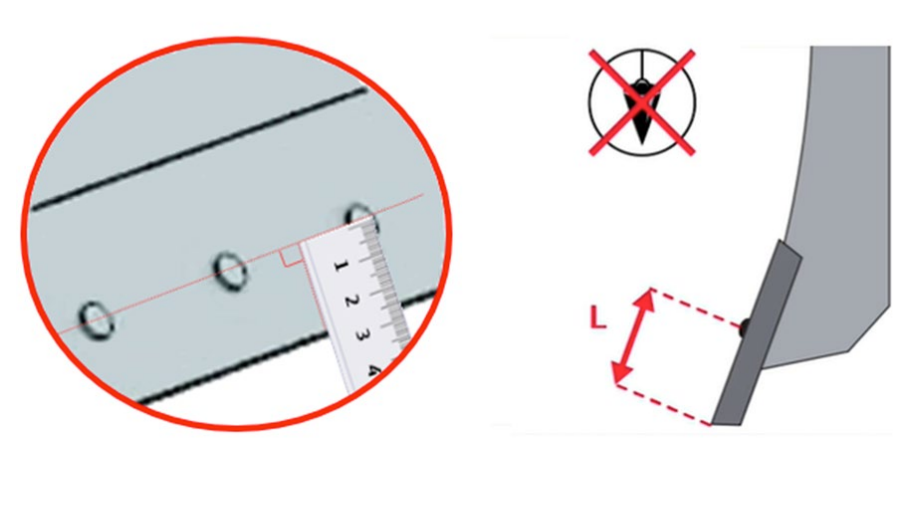

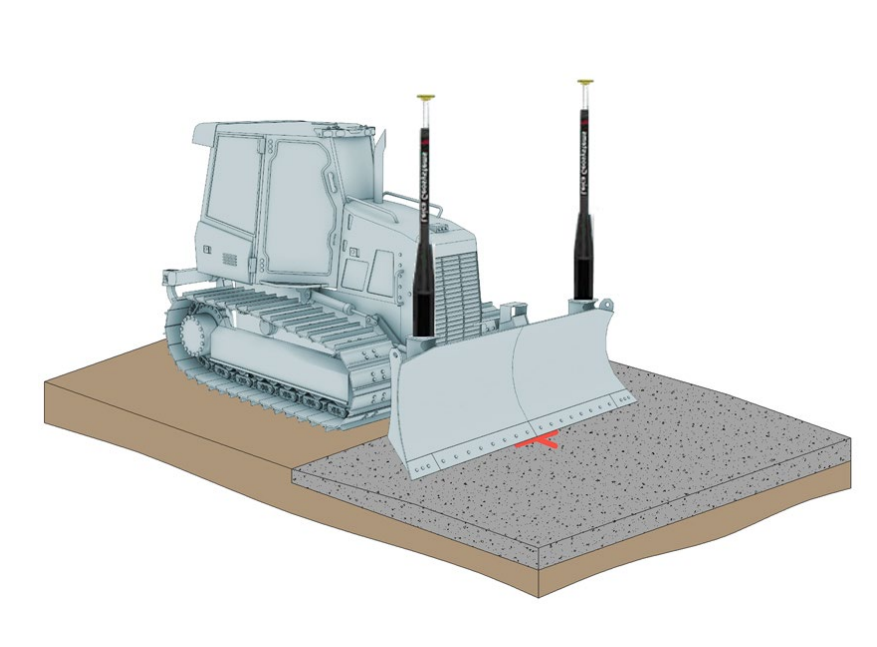

Determine an appropriate place to measure the blade wear. Due to the fact that the blade will wear unevenly at different points, the best method is to take an average measurement at various points on the blade.

Measure flat against the blade, the distance from the center of the cutting edge bolts to the tip of the blade. Do not measure plumb.

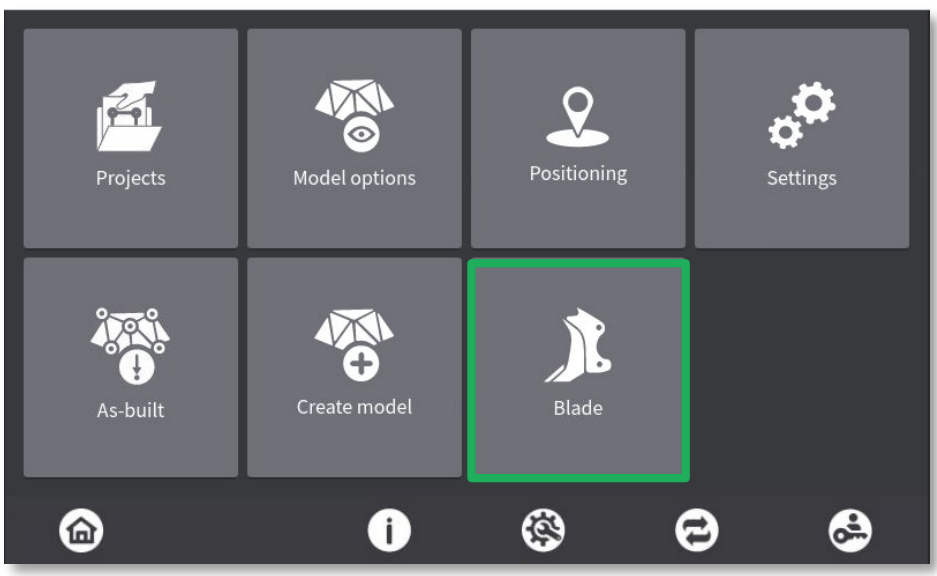

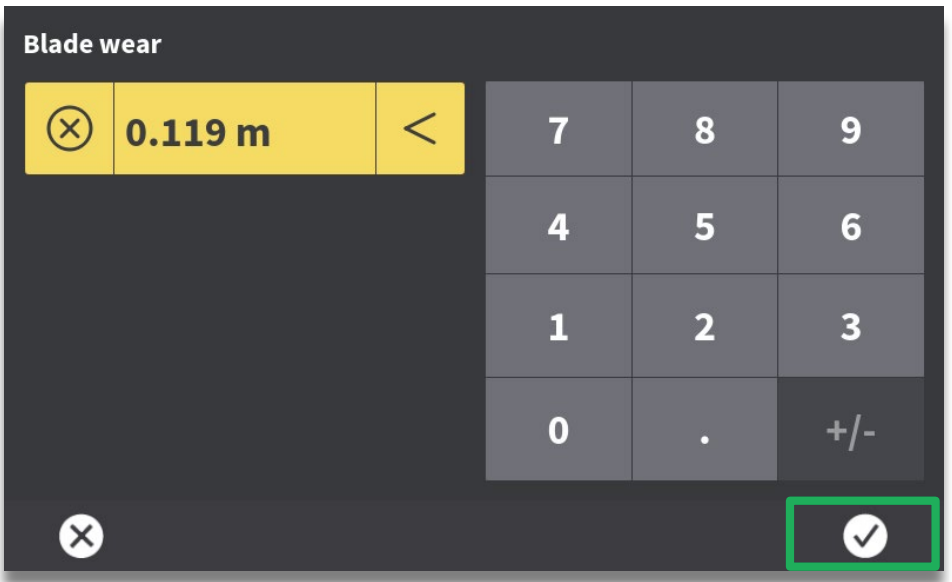

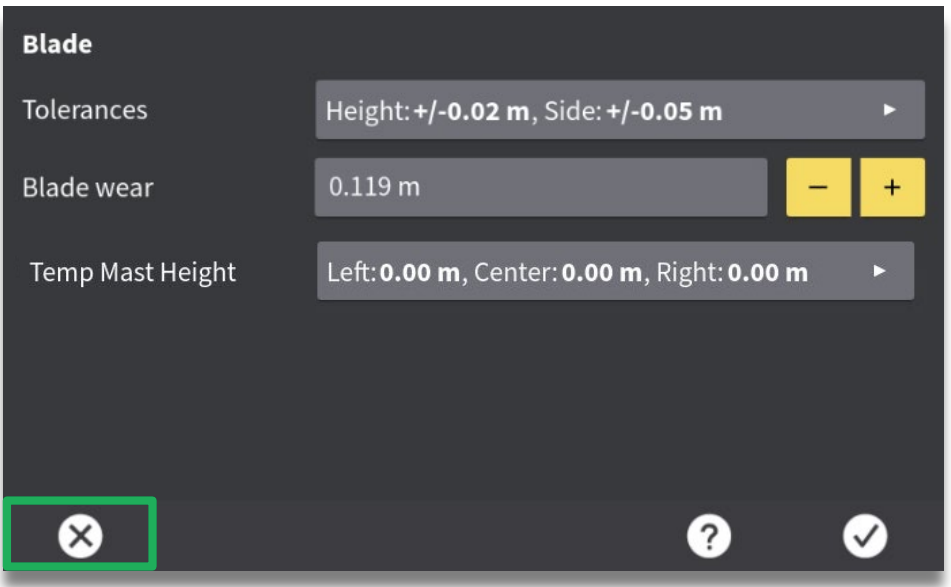

Select the Blade menu.

Alternatively, you can tap on the Blade Wear Value Field to type in the measurement. Hit the check mark to accept.

Press [X] to return to the Run Screen.

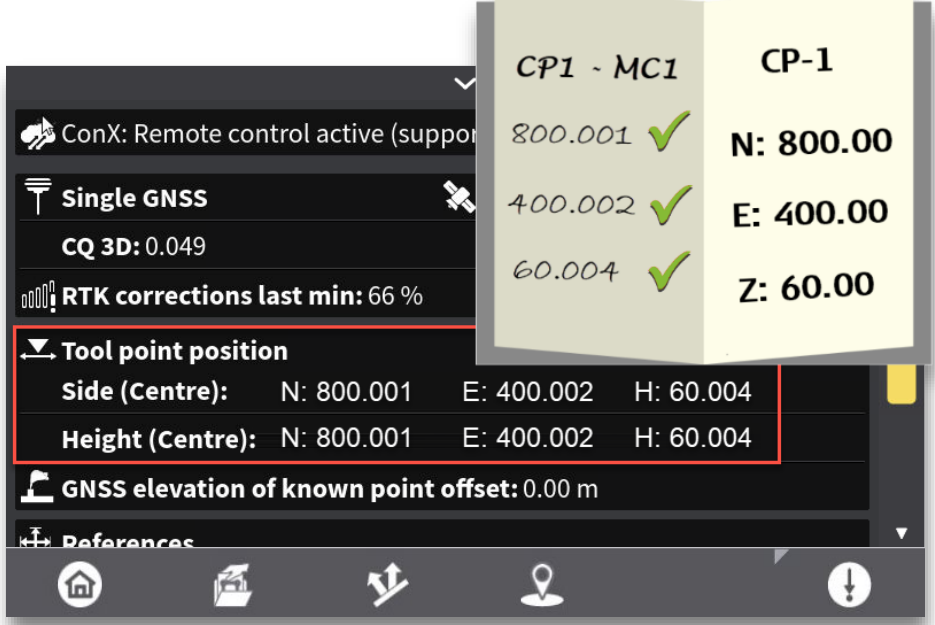

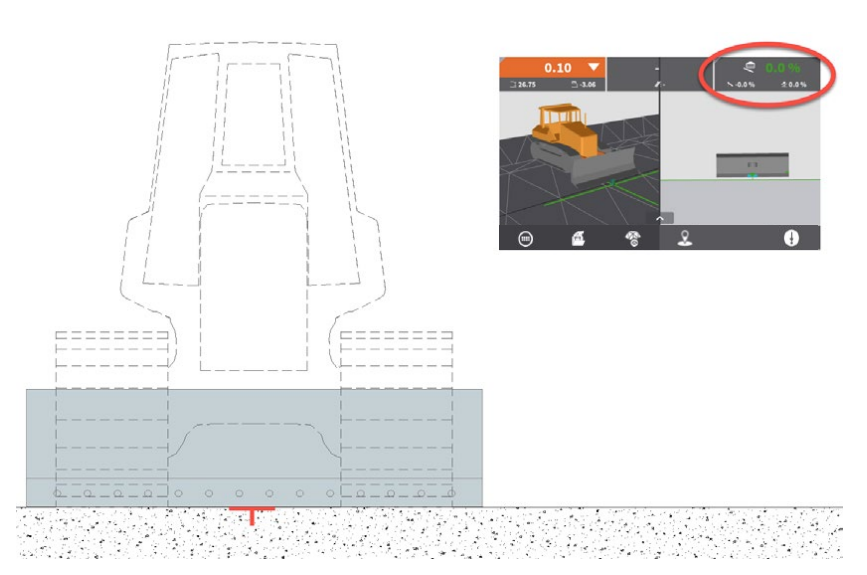

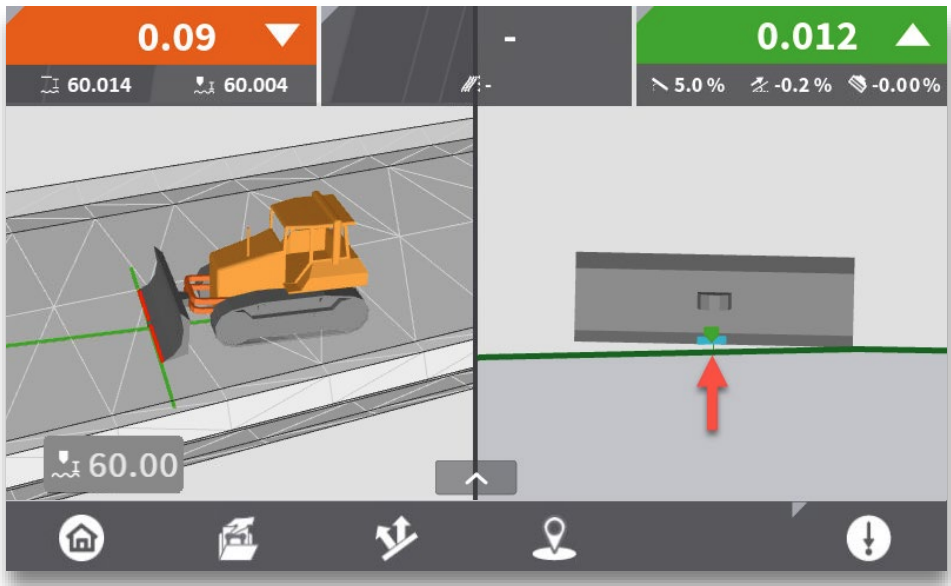

Position the center of the blade over a known reference point.

Make sure the Blade is Level with Tracks and Slope is at 0%.

Use the [UP] and [DOWN] buttons to adjust the Height Reference (Green Arrow) to the Center of the Blade.

Compare the Height Tool Point Position to the Known Position of the Control Point. If differences exceed project specifications, please contact your local ABTECH Representative.